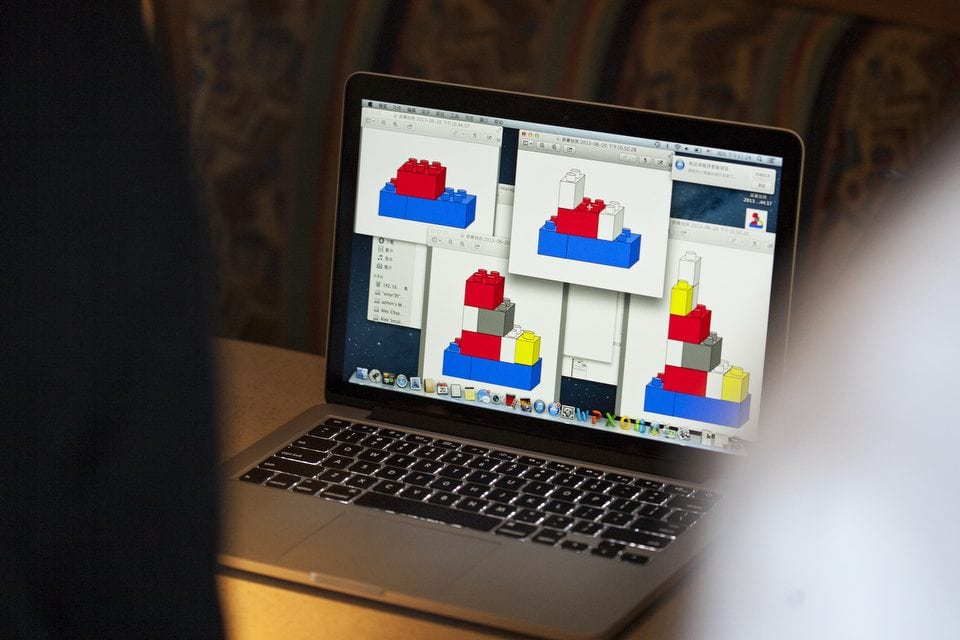

It's a beautiful afternoon on board the MV Explorer and Professor Tim Laseter's students are busy playing with Legos. It's not what you think – the Legos are a teaching aid, and the students in this Operations Management class are taking part in a simulation. For this class period, they're employees of Gazogle Inc., and their goals are to assemble and deliver finished Lego products to their client, while continuously improving the efficiency of the process. Failure to meet production quotas or delivering defective units are penalties, salaries are paid to every employee, and rent is paid for each work station/table. With two teams competing, the atmosphere is serious, competitive, and, really, quite fun.